Manufacturing

for Record Labels

Free Marketing Checklist

Let’s discuss the current state of vinyl manufacturing, supply chain concerns, price increases, and production delays...

There’s a lot of confusion surrounding the current state of music manufacturing when it comes to pressing vinyl, manufacturing CDs, and making cassette tapes!

Let’s look at some of the areas that are causing problems for factories, artists, and record labels!

The Current State of

Music Manufacturing

Material Shortages

The plastics manufacturing industry (PVC) is facing an unprecedented resin and raw materials shortage not seen in decades, costs have increased by over 75%.

Materials are wanted by other industries. Products like paper and PVC are in high demand in many industries, not just for record and tape manufacturing.

The “Amazon” problem… As online order increased during COVID, Amazon (and other retailers) started to dominate the cardboard supply. Similar material is used for record jackets and shipping boxes.

The demand and shortage for nickel (used to make record stampers) has increased drastically (used in batteries in electric vehicles) while one of its primary suppliers (Russia) has increased prices.

Factory Delays

As with any company, employees call off sick with COVID or are being cautious if they have COVID symptoms.

European factories operate on gas from Russia which has become less reliable and more expensive.

COVID restrictions such as social distancing, screening, and general employee safety have made human operations less efficient.

The prevalent computer “chip” shortage has even affected the newer pressing machines that

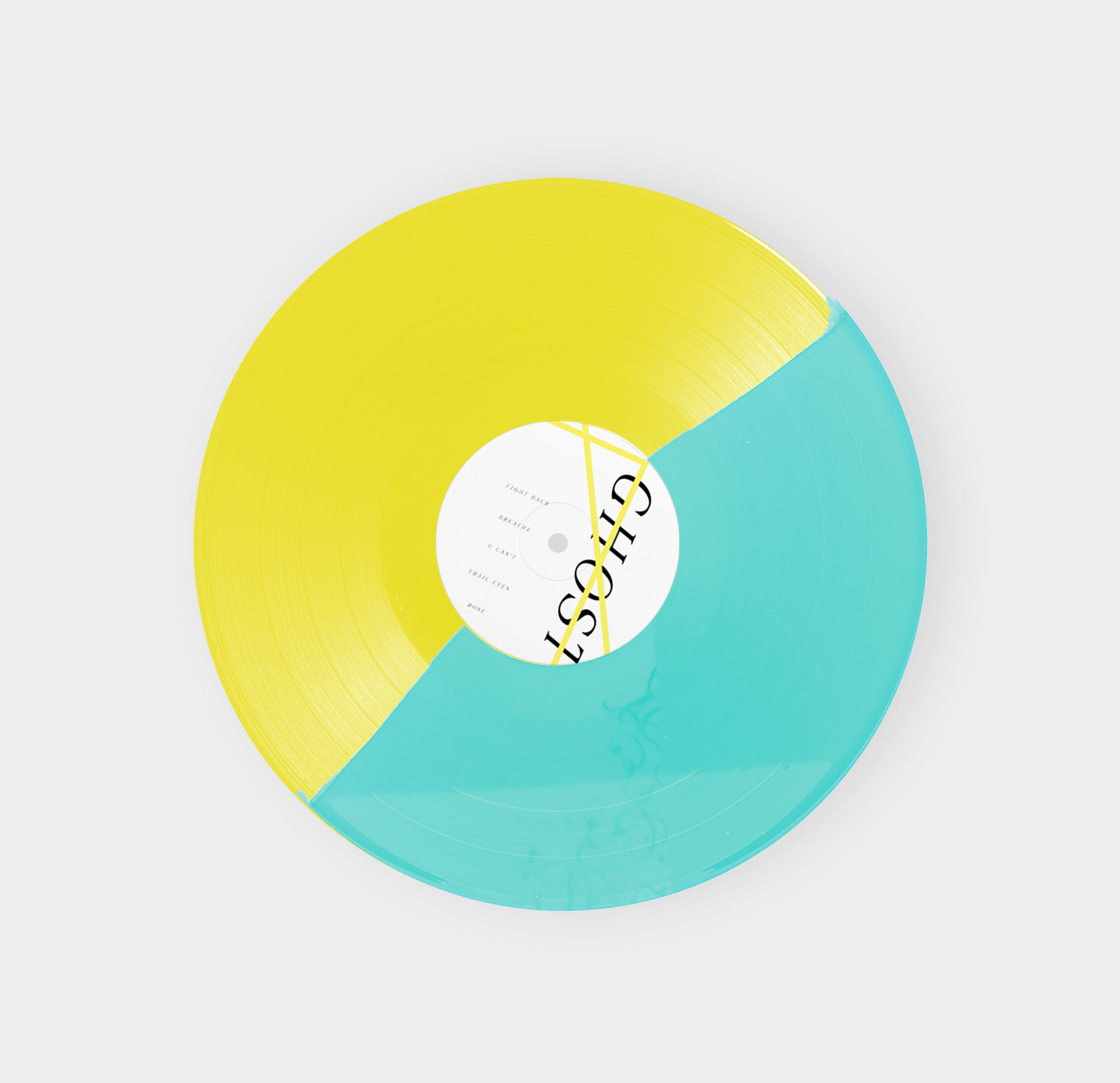

As the popularity of color vinyl increases, the process of cleaning in between color changes can slow down the overall production times.

Pricing Concerns

Gas prices have increased due to the war, which has increased the cost of delivery and running the factories.

A big concern of artists and labels is if these new post-COVID, post-WAR prices may never go back down!

In the past, price increases from materials suppliers came with a few months notice and were nominal increases. Today, they happen overnight. If your pressing plant rejects the prices, the supplier will simply send the material to another factory in another sector.

All of the material shortages (mentioned earlier) have all compounded to drive up the overall manufacturing price!

Market Demand

Demand for vinyl (and physical music) has only increased and intensified! While great for artists, it’s intensified production delays!

Perceived value of physical media is incongruent with the actual costs!

How high does the price of vinyl have to get before people stop buying it?

Newer and younger generations are continuing to discover and consume vinyl, CDs, and cassettes!.

Currently, there isn’t enough vinyl to meet the demand of consumers!

RECORD LABEL

ACADEMY

The Complete A to Z of Building and Growing an Independent Record Label.

Music Manufacturing FAQs

Will we see multiple physical music formats co-existing together?

This seems to be a trend that we’re seeing among music listeners: CDs in the car, streaming on the go, vinyl for the living room, tapes in the bedroom or office, etc. A place and utility for each format.

How should a record label manage delays and price increases?

The best solution is to get started as early as possible. Try to get the finished masters from your artist (nearly) a year before they want the album to come out. At the very least, start preparing for manufacturing while the artist is still recording…

Can these vinyl pressing delays drive more interest in CDs?

That has yet to be seen, but CD manufacturing numbers are starting to curve upwards, CD manufacturing still greatly exceeds cassette manufacturing, which is also growing.

How many copies should I get made?

The sweet spot for indie artists and labels is 300 units. The cost of pressing 100 units may be cheaper, but it would likely require you to sell all 100 at ~$25 each, just to break even. Whereas, quantities of 200-300 trigger “price breaks” and make the overall cost per unit much less.

Building a successful record label shouldn’t be a mystery.

Drop me a line if there’s anything I can help you out with…

Or book a private one-on-one to chat about your label’s specific needs!

-Scott

Vinyl Hacks!

Making Tapes!

Other Record Labels Podcast

Featuring interviews with…